Different machines are best suited for repairing damaged areas depending on the method and processes:

Repairs to damaged areas

Repairs to damaged areas include a wide of range of treatments for potholes, frost heave, sinking, eruptions at the edge of the road surface, thinning of the top covering and network cracks in asphalt surfaces, and even damage to footpaths.

Sustainable methods can be used to protect roads against further degradation, enabling them to be used for many more years without major action. Repairs are also ideal as preparation for subsequent work on the surface.

As every damaged area has a different size, shape and depth, maximum flexibility is demanded from the user and the machine. Efficient repair therefore means interrupting traffic for as short a time as possible and flexibility to adapt to every situation.

To ensure an optimum solution for these requirements, we have developed the two schäfer-technic originals Blow-Patcher and Mini-Mix. These machines are manoeuvrable, capable of mixing their material on site and can be configured at any time according to the situation.

A repair train enables individual repair tracks to be precisely sprayed, spread and rolled in a single operation.

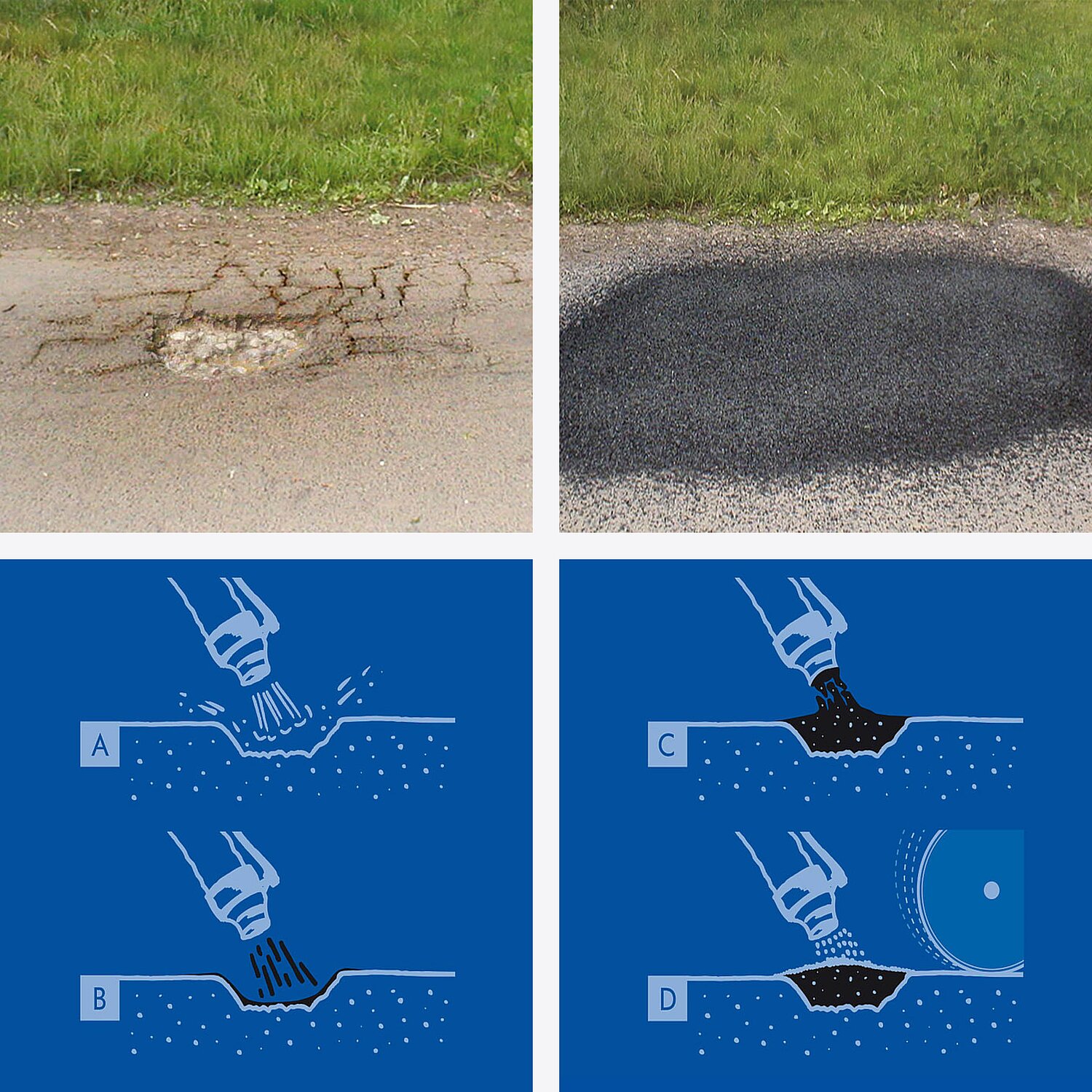

Patching with the Blow-Patcher

The jib arm on the Blow-Patcher enables damaged areas to be treated with flexibly adjustable cold mixture. The mixing head on the jib arm offers the operator convenient use of multiple applications:

Blow off

Dust and dirt is removed from the damaged area with compressed air or also with a water-spray attachment where necessary.

Spraying

The mixing head even sprays the cleaned surface with a bitumen emulsion to create the best possible bond with the substrate.

Filling

High quality chippings are coated with bitumen emulsion in the mixing head and then fed into the damaged area. The mixing ratio and grain size are adjusted according to the local layer and are installed directly.

Gritting

High quality chippings are coated with bitumen emulsion in the mixing head and then fed into the damaged area. The mixing ratio and grain size are adjusted according to the local layer and are installed directly.

Rolling

Depending on the design, the machine has press rollers that compress the treated area and minimise the occurrence of loose chippings.

Repairs with cold asphalt mixture

Cold asphalt mixture is used. Thanks to its flexible application options, this is more economical, more environmentally friendly and safer than conventional asphalt. At the same time, cold asphalt offers the same durability. This pioneering method has been continuously developed thanks to decades of construction site experience, and the materials used have been perfected. Today, it meets the highest quality standards.

The Mini-Mix machine concept allows consistent and precise production of different cold asphalt mixtures. The formulation can be adapted to the relevant application situations. The Mini-Mix supports practical construction site operation and efficient processes. It also complies with the latest technical and formal requirements.

Thanks to a special mixer with pivoting outlet, the Mini-Mix allows application of asphalt mixtures manually or using a paver. Optimised for start/stop operation, they enable fast and high quality treatment of small and medium-sized damaged areas.

Material losses

The pivoting mixer enables potholes, broken road edges and footpaths to be repaired manually.

Cracks and joints

Ruts, cracks, network cracks and middle seals can be professionally built over using a paver.

Reprofiling of road edges

Manual application or use of a paver can compensate for indentations and uneven areas. The transverse profile of the road can also be corrected.

Advantages compared to conventional methods:

- Conserves resources due to optimised material quantity

- Energy saving, as heating of the material is not required

- Protects the environment due to low emission figures during production

-

High application quality due to mixture adapted to road conditions

- Low manufacturing costs

- More efficient construction site due to flexible manual or mechanical application

- Fast re-opening for traffic

Partial repairs with the RZA-Vario

The RZA and RZA-Vario repair trains allow partial repairs with surface dressing to be carried out, in some cases even without closing the road to traffic.

Selecting repair tracks

The repair tracks and the road sections to be treated are selected on the control station on the trailer or directly in the driver cab.

Spraying

The selected track is automatically and precisely sprayed by the spray bar. The binding agent is thus only sprayed onto the surfaces to be treated.

Spreading

Directly afterwards, the sprayed surfaces are then spread with chippings. Spraying and chipping spreading reliably function continuously and covering the same areas.

Rolling

Press rollers on the machine compress the treated tracks and thus complete the work process.