Innovative and reliable processes

Every schäfer-technic machine is designed and developed in conjunction with our customers. As a result, you benefit from custom-made and state-of-the-art equipment on your construction site.

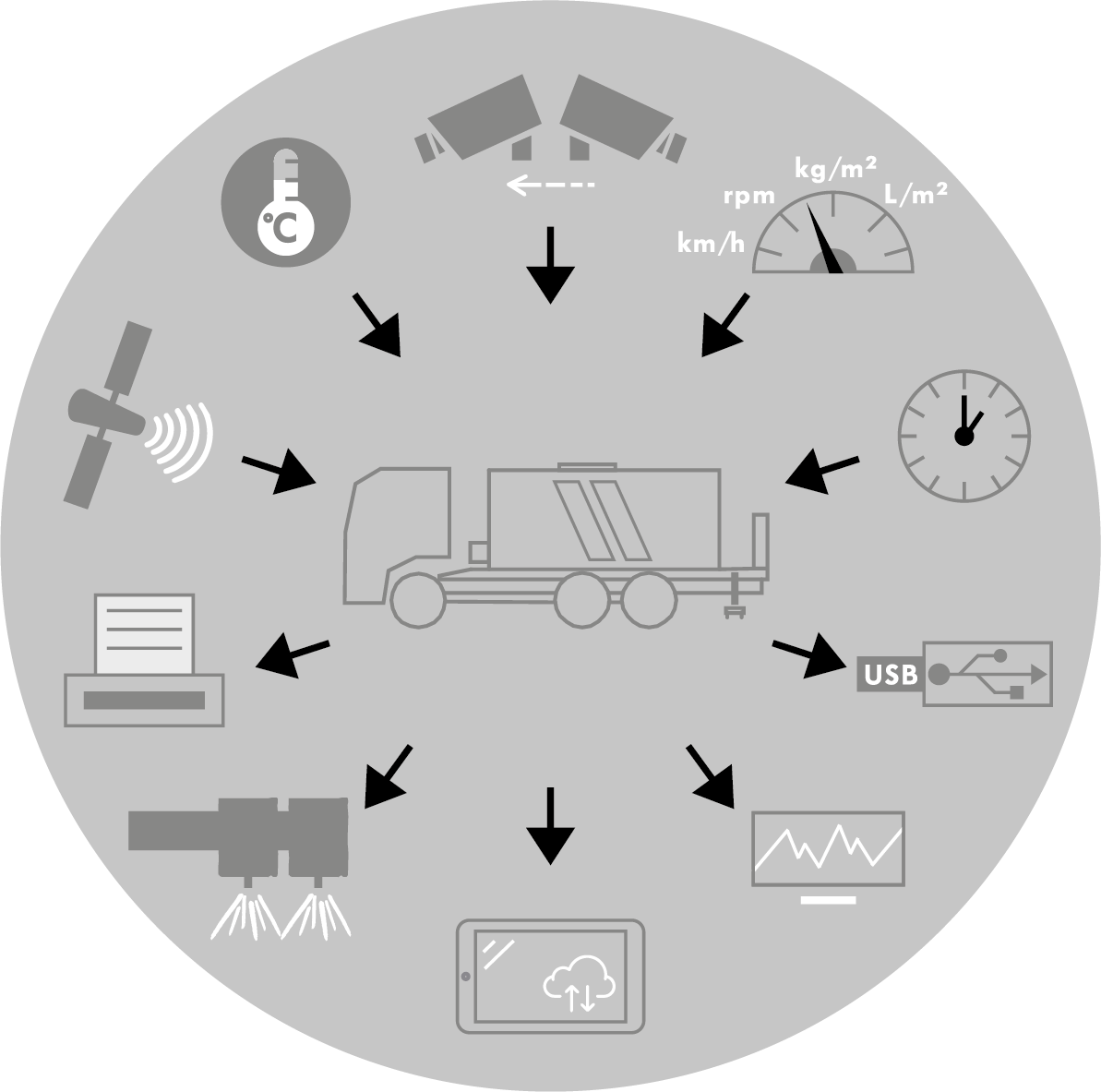

Comprehensive features, from exact dosing when working to entry and retrieval of reliable data through to digital communication, we support you where you need us most.

We can also provide comprehensive advice for more specific requirements and identify a customised solution for you.

PREPARATION FOR LAYER BONDING FOR ASPHALT APPLICATION

A secure bond between the individual asphalt layers is a key requirement to ensure asphalt structures have a long service life. A full and permanent bond ensures that the asphalt layer structure can support the required loads in the long term.

schäfer-technic offers a machine with the right equipment for any size and requirements on a construction site.

MICRO SURFACING

The micro surfacing method enables road surfaces to be quickly covered with a high quality asphalt mixture. Construction sites can normally be opened to traffic again after around 20 minutes.

schäfer-technic supplies micro surfacing and Mini-Mix machines in different versions and configurations, enabling high quality asphalt mixtures to be produced and laid.

REPAIRS TO DAMAGED AREAS

Potholes, frost heave, sinking, eruptions at the edge of the road surface, thinning of the top covering, network cracks in asphalt surfacing and pavement damage can all be repaired with the right machine. Optimum repairs permanently eliminate the damage and maintain road safety. The road surface can also be prepared for further work (e.g. surface treatment).

schäfer-technic supplies repair trains, Mini-Mix and Blow-Patcher machines for repair work.

SURFACE DRESSING AND SEALING

Surface treatment involves applying a hot binding agent or bitumen emulsion, and then spreading coarse aggregate. Bond coat spraying can also be carried out with a bitumen sprayer and chippings can be added in a separate operation. Alternatively, a single combined machine can carry out both of these functions.

schäfer-technic supplies bitumen sprayers, chipping spreaders, surface dressing machines and repair trains for surface dressing.

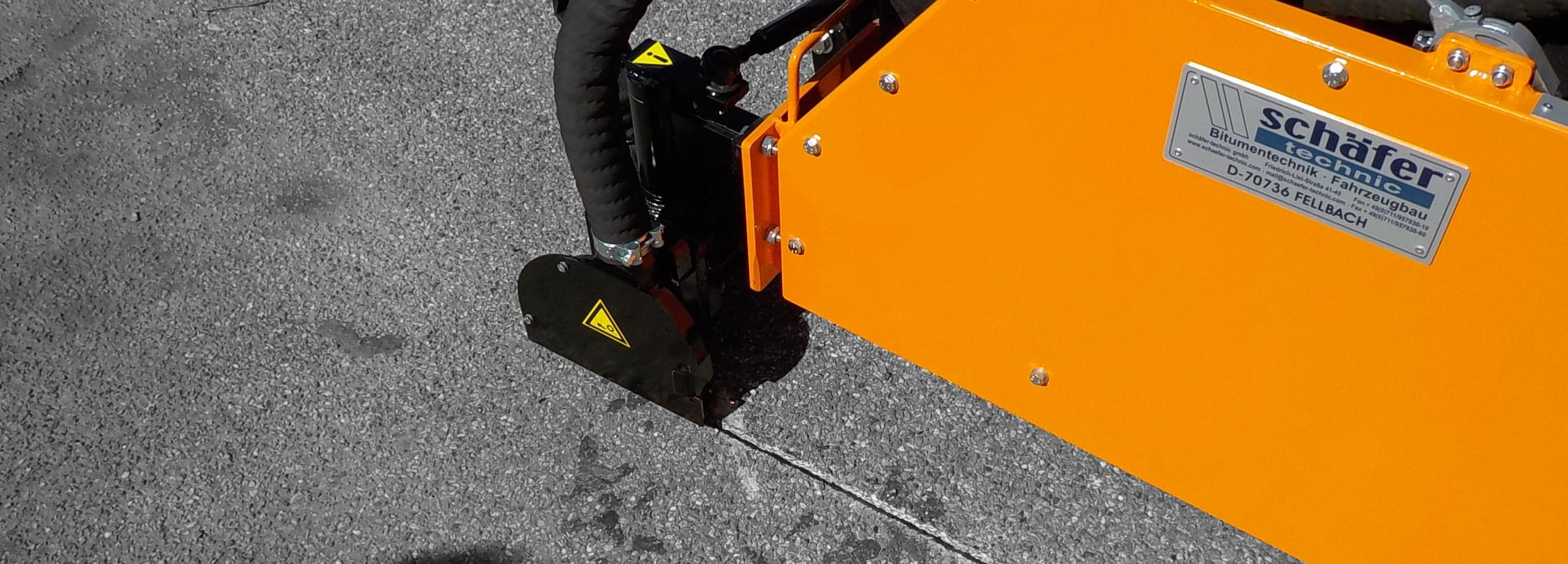

SEALING TECHNOLOGY FOR CONCRETE AND ASPHALT

Sealing technology methods use polymer-modified bitumen products for sealing cracks, joints and surfaces. Specially adapted machines are necessary for processing these materials. They enable professional work and repairs to be carried out in compliance with relevant standards.

The schäfer-technic range includes sealing cookers, laying machines for surface sealing, milling machines and more.

- Show all

All products: You can find our entire range of machinery below. When you select a method, the appropriate machinery types are displayed.